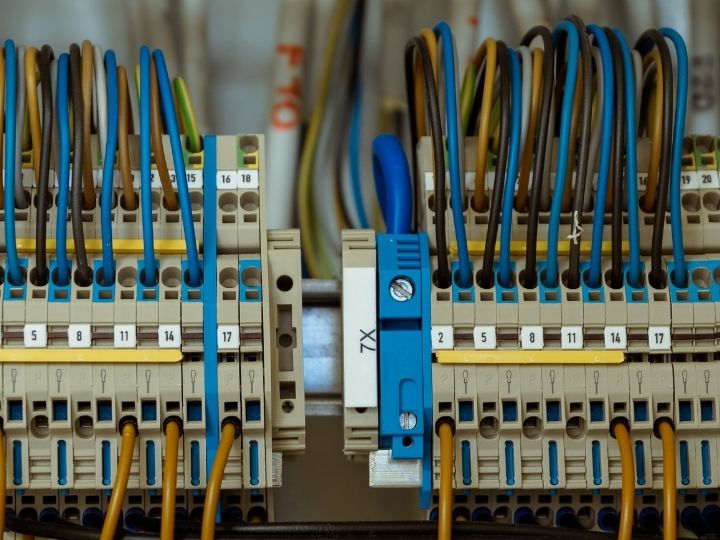

If you own a factory, office, or shop, electrical maintenance is crucial for your staff’s safety and the lifetime of your equipment. Avoiding electrical maintenance can result in electrical fires, system breakdowns, power outages, and damage to your electrical systems. All it takes to cut these risks is a little forethought and caution.

What is Electrical Maintenance?

Electrical maintenance ensures that electrical equipment is in excellent operating condition. It involves testing and fixing electrical equipment to avoid issues resulting in a power outage or an accidental fire.

What is the Purpose of Electrical Maintenance?

Some of the most elaborate and complex systems in use are electrical components. Repairing and maintaining systems and equipment that supply electricity requires the appropriate training.

Electrical problems can cause injury and destroy property if they are not maintained. Several laws that deal with safety at work and home include the need for frequent inspections. One of the most incredible things to do is engage a professional to examine all electrical systems at your home.

It’s critical to do routine electrical maintenance on all the electrical systems in and around your offices, shops, and factories. Electrical maintenance improves the efficiency of your production lines and electrical systems. It creates a safe environment free from various risks.

What is the Importance of Electrical Installation and Maintenance?

Safeguards Your Equipment

Your equipment can last longer if you maintain and examine your electrical system. Mechanical maintenance is necessary for electrical systems to operate faultlessly.

Lowers Energy Costs

Regular maintenance of your electrical system can help you save money on electricity. An electrician can diagnose any power consumption issues and assist you with cost-effective energy-saving measures.

Safety

One of the main factors in factory fires is electrical malfunctions, and wiring issues always play a part in these incidents. Over time, the heat from the wire can deteriorate its protective covering to the point where it fails.

Electrical maintenance can enhance you and your staff’s safety in the building. A maintenance electrician will be able to let you know if there are any problems with your systems and whether anyone is in danger of electrical faults.

Saves Money

You can avoid any potential problems with electrical servicing. It can also stop existing issues from growing worse and costing more money.

What are the Types of Electrical Maintenance?

Preventive Maintenance

Preventive maintenance aims to identify and address issues before they arise. Examine a system or a piece of equipment thoroughly to look for any indications of deterioration or impending failure. You should replace the damaged components right away. This approach of mechanical maintenance will avoid entering “crisis mode” if something breaks.

Predetermined Maintenance

Predetermined maintenance differs from other maintenance strategies in that the maintenance staff follows guidelines and suggestions offered by the original manufacturer.

Corrective Maintenance

Corrective maintenance problems lower the need for emergency repairs and increase worker safety. For instance, a maintenance worker may discover that a pipe in an HVAC system is not functioning correctly when doing a routine maintenance check or while resolving another issue. The problem is then resolved or replaced during planned corrective maintenance at a later date.

Condition-Based Maintenance

Machines and systems are monitored for warning indicators of potential failure rather than subjected to routine inspection. Specialists track the system’s performance. They note variables like temperature, power, the presence or absence of moisture, etc.

Predictive Maintenance

Predictive maintenance involves monitoring systems using sensor equipment. These sensors are linked to system components and provide continual, real-time data to software. After analyzing this data, the program alerts maintenance specialists to impending risks.